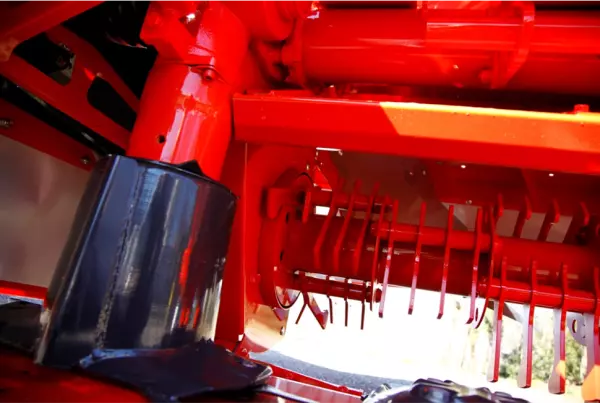

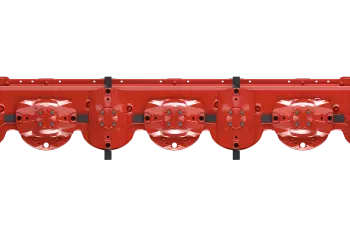

Lubed-For-Life Optidisc® Elite Cutterbar

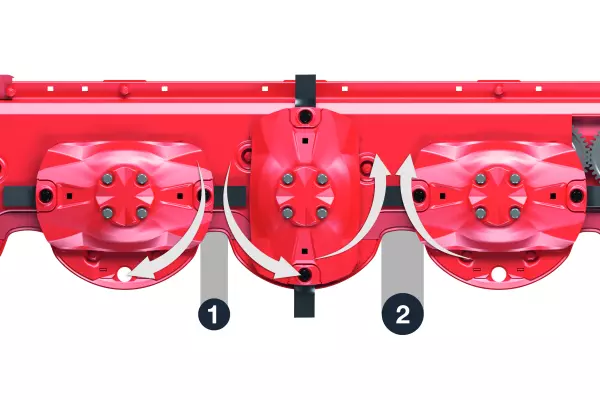

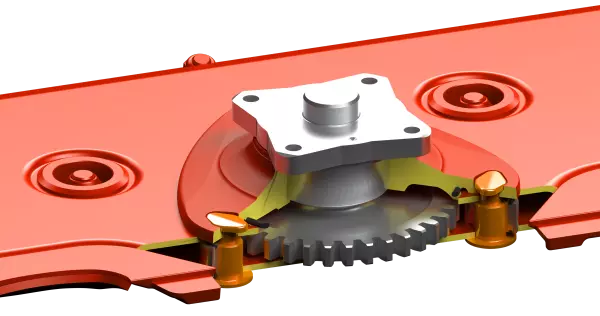

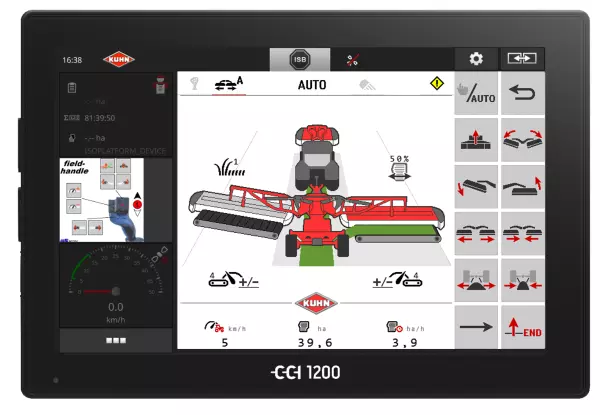

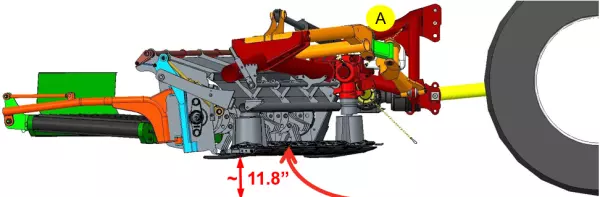

The Optidisc® Elite cutterbar provides a flat, streamlined profile so that soil and crop residue do not accumulate, and material flows smoothly, even in heavy, difficult crop conditions. These mowers come standard with the Fast-Fit® quick release knife system. Optidisc cutterbars are designed and tested with a zero oil change interval. The highly-polished gears and synthetic gear oil ensure that this system does not require any regular internal maintenance, eliminating the need for cutterbar oil changes throughout the life of the machine.