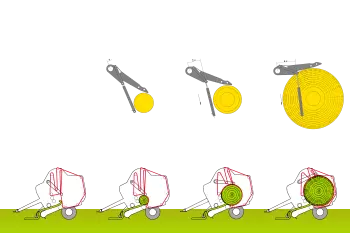

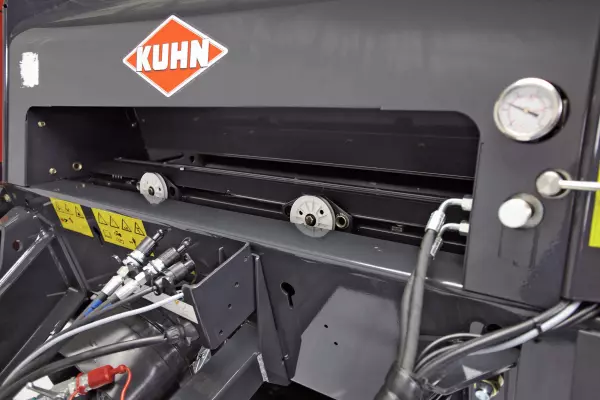

| 1 starter roller – 2 bale chamber rollers – 5 belts | 1 starter roller – 2 bale chamber rollers – 5 belts | 1 starter roller – 2 bale chamber rollers – 5 belts | 1 starter roller – 2 bale chamber rollers – 5 endless belts | 1 starter roller – 2 bale chamber rollers – 5 endless belts | 1 starter roller – 2 bale chamber rollers – 5 belts | 1 starter roller – 2 bale chamber rollers – 5 belts | 1 starter roller – 2 bale chamber rollers – 5 belts | 1 starter roller – 2 bale chamber rollers – 5 endless belts | 1 starter roller – 2 bale chamber rollers – 5 endless belts |

| Standard with heavy-duty bearings and seals | Standard with heavy-duty bearings and seals | Standard with heavy-duty bearings and seals | Standard with heavy-duty bearings and seals | Standard with heavy-duty bearings and seals | Standard with heavy-duty bearings and seals | Standard with heavy-duty bearings and seals | Standard with heavy-duty bearings and seals | Standard with heavy-duty bearings and seals | Standard with heavy-duty bearings and seals |

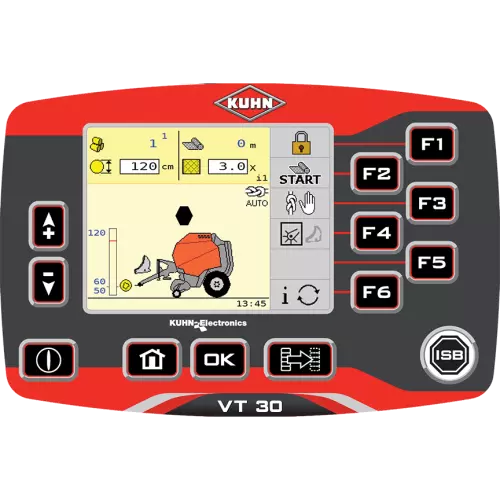

| 870-2,900 psi (60-200 bar) manual | 870-2,900 psi (60 - 200 bar) manual | 870-2,900 psi (60 - 200 bar) manual | 870-2,900 psi (60-200 bar) manual | 870-2,900 psi (60-200 bar) manual | 870-2,900 psi (60-200 bar) manual | 870-2,900 psi (60 - 200 bar) manual | 870-2,900 psi (60 - 200 bar) manual | 870-2,900 psi (60-200 bar) manual | 870-2,900 psi (60-200 bar) manual |

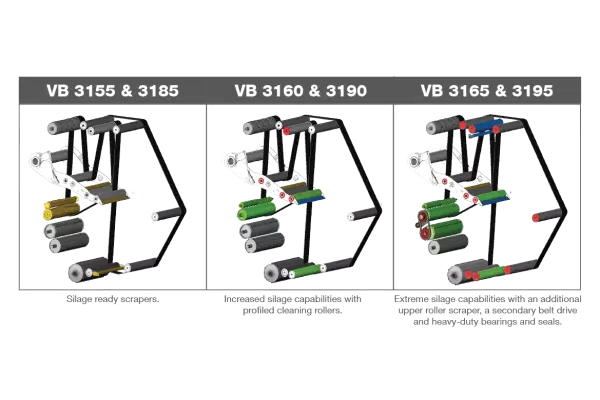

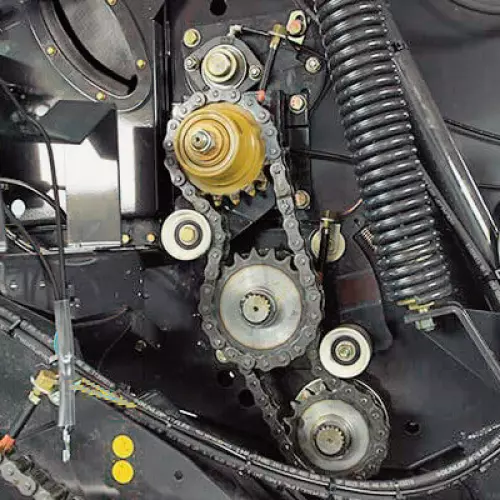

| 1 starter roller - 2 bale chamber rollers- 5 belts | 1 starter roller - 2 bale chamber rollers- 5 belts | 1 starter roller - 2 bale chamber rollers- 5 belts | Driven clean roller in front segment including second belt drive | Driven clean roller in front segment including second belt drive | 1 starter roller - 2 bale chamber rollers- 5 belts | 1 starter roller - 2 bale chamber rollers- 5 belts | 1 starter roller - 2 bale chamber rollers- 5 belts | Driven clean roller in front segment including second belt drive | Driven clean roller in front segment including second belt drive |

| Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Electric pressure settings in cab as standard | Electric pressure settings in cab as standard | Electric pressure settings in cab as standard | Electric pressure setting in cab as standard | Electric pressure setting in cab as standard | Electric pressure setting in cab as standard | Electric pressure settings in cab as standard | Electric pressure settings in cab as standard | Electric pressure setting in cab as standard | Electric pressure setting in cab as standard |

| Standard laced belts | Standard endless belts | Standard endless belts | Endless belts with secondary drive roller | Endless belts with secondary drive roller | Standard laced belts | Standard endless belts | Standard endless belts | Endless belts with secondary drive roller | Endless belts with secondary drive roller |

| Optional | Optional | Optional | Standard | Standard | - | Optional | Optional | Standard | Standard |