Pickup

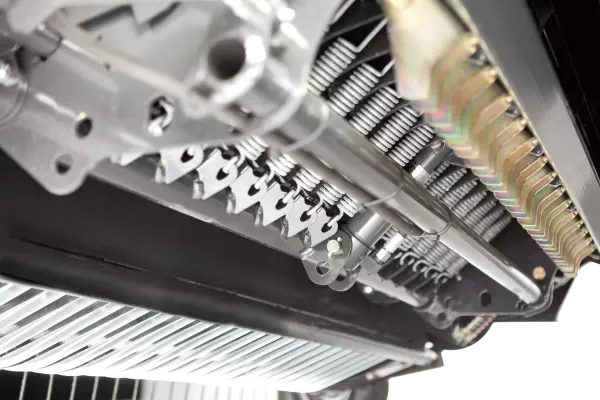

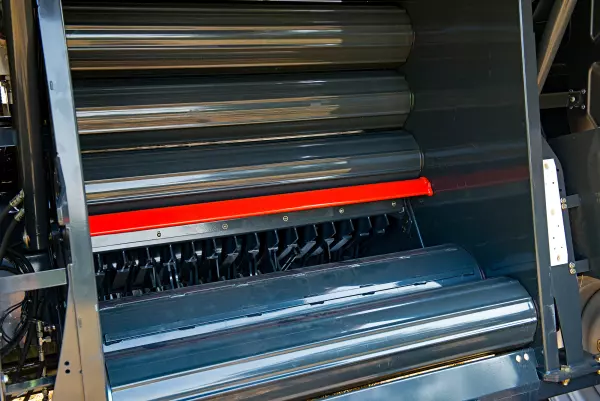

The reliable cam-track steered pickup is built for optimal crop intake, featuring a standard crop roller and a wide 90.55 in. (2.30 m) working width. With four rows of tines spaced at 2.40” (61 mm), it ensures consistent, efficient gathering. The pendulum design, cam-track guidance and overload clutch enhance durability and control. Fixed pickup wheels come standard, with optional pivoting wheels available for added flexibility in the field.